DTD&O 2024

Paris | November 21, 2024

PROGRAM | SPEAKERS | COMMITTEE | LOCATION | REGISTRATION

INTERNATIONAL FORUM

ON DIGITAL TWIN DESIGN & OPERATIONS

EXPLORING THE VALUE AND IMPACTS OF DIGITAL TWINS IN COMPLEX SYSTEMS

Paris | November 21, 2024

The 2nd edition of the “International Forum on Digital Twin Design & Operations“ is an upcoming event that this year aims at exploring the value and impacts of digital twins in complex systems.

This forum will bring together experts, researchers, and industry leaders from around the world to share their insights, experiences, and knowledge on digital twin solutions. The event will provide a unique opportunity to learn about the latest developments in digital twin design and operation, including the challenges and opportunities of creating and managing digital twins in different industrial sectors.

Attendees can expect to engage in thought-provoking discussions, interactive sessions, and networking opportunities with peers and experts in the field.

The forum promises to be a valuable platform for exploring the future of digital twin technology and its potential to revolutionize complex industrial processes

A professional networking event

What can you expect from the conference?

As industries continue to evolve and become more complex, it is becoming increasingly important to leverage advanced technologies and tools to optimize operations. Digital twins, which are virtual replicas of physical systems or functional processes, offer a powerful solution to this challenge, enabling industries to simulate, monitor, and optimize their processes in real-time. By combining digital twins with systemic thinking, a holistic approach to problem-solving that takes into account the interconnectedness of all system components, industries can gain deeper insights into their operations and optimize them for maximum efficiency and productivity.

At our conference specifically focused on digital twins and systemic thinking in industry, participants will have the opportunity to:

➤ Learn from leading experts in digital twins, systemic thinking, industrial product and processes modeling & simulation, and enterprise architecture approach,

➤ Discover the latest tools and technologies for industrial process strategic planning & operational optimization,

➤ Network with industry professionals and researchers,

➤ Explore papers, case studies and real-world applications of digital twins, industrial product and processes modeling & simulation.

A one-day event exploring the latest innovations in digital twin for industrial processes strategic planning & operational optimization.

Program

9h00

Opening Keynote

Welcome Speech: Leveraging Digital Twins in Production Engineering

Nabil Anwer (Chairman of the conference), CIRP Fellow – Professor | Paris Saclay University

Digital Twins are digital representations of real-world entities that are continuously updated through dynamic, bidirectional communication throughout the lifecycle of this sophisticated system. Their development and use in production engineering present new research, development, and innovation opportunities in digital transformation. This talk aims to provide an up-to-date overview of digital twin research in production engineering, explaining their foundational principles from an academic perspective. From supporting and enhancing engineering activities with digital twins to the methodological development and operation of digital twins, this talk will address the challenges and prospects of digital twins from various national and international scientific organizations’ perspectives.

9h30

How to manage complexity through developing new Digital Twins Design & Operation solution

Setra Rakotomavo, Head of IT Strategy Department, La Poste

10h00

From smart cities to IoT devices; standards supporting digital twins to cover multiple domains .

Antonio Kung, Executive board member – TRIALOG

A survey of digital twin standards will be provided. The approach taken by ISO/IEC 30188 (digital twin reference architecture) to enable the construction of implementation architectures supporting different verticals (e.g. smart manufacturing, energy, smart cities, health) will be presented. Two standards under development to support data spaces will be described: ISO/IEC 30151 (extraction and transaction of data products) and ISO/IEC 30152 (guidance on the connection of IoT and digital twin to data spaces). One standard to support interoperability in complex ecosystems will be further explained, ISO/IEC 21823-5 (IoT behavioral and policy interoperability). Finally a roadmap perspective will be proposed.

10h30

Coffee break

11h00

Thing in the future, a flexible digital twin platform developed by Orange for industrial applications

Laurent Bouskela, Partnerships for Research & Orange Digital twin platform, ORANGE

Orange has been developing a digital twin platform called “Thing in the future” for several years. This has been accompanied by the implementation of collaborative research projects for a wide range of use cases and a number of experiments in different areas. We are now focusing on the delivery of customer use cases, in particular with Orange France for network digital twins, with Orange Business Evolution Platform for the composition of cloud and network services, and with IRT-SystemX within the JNI (“Jumeaux Numériques Industriels”) program for industrial digital twins. It is worth mentioning that the reduction of the carbon footprint is increasingly present and can benefit from the ability of digital twins to aggregate different types of data.

11h30

Auto-Twin: Autonomous Digital Twins for Enhancing Circularity and Sustainability in Industrial Value Chains

Andrea Matta, Professor of Manufacturing, Editor in Chief of Flexible Services and Manufacturing Journal, Politecnico de Milano

The Auto-Twin project aims to revolutionize industrial value chains by developing autonomous Digital Twin technologies that enhance circularity and efficiency in production systems. Leveraging advanced data-driven methods, Auto-Twin creates high-fidelity digital replicas that dynamically adapt to real-time changes across the value chain. This project focuses on four key objectives: the automated generation and maintenance of digital twins, precise tracking and tracing of products across circular value chains, closing skills gaps through augmented intelligence, and intelligent decision-making at strategic points, known as “Green Gateways.” Auto-Twin’s platform integrates cutting-edge AI techniques, process mining, and explainable analytics to optimize decision-making, improve resource utilization, and extend product lifecycles. Through collaboration with diverse industry partners and real-world pilots, Auto-Twin seeks to establish new standards in sustainable manufacturing, driving the EU closer to its circular economy goals by reducing waste, maximizing resource efficiency, and fostering innovation across industrial sectors.

12h00

Overcoming Deployment Challenges and Structuring Airbus Portfolio to Leverage Digital Capabilities

Pierre-Jean Rivière, Digital Twin Solutions Leader, AIRBUS

How to use complementary digital twins to create a federation of digital twins in order to deploy them at a larger scale and to generate compounding value?

Three main types of challenges are considered as obstacles for the deployment of digital twins: the technical challenge with multiple data sources and heterogeneous solutions, the organizational challenge to ensure a global optimum within a transversal approach and the methodological approach, to mutualise lessons learned and failures.

To face such challenges, a digital twin portfolio clarifies the strengths and communalities to leverage Digital Twin Capabilities.

12h30

Lunch & Poster Session

Poster #1: JNI5 – Digital Twins for Assessing, Managing, and Improving the R3 of Critical Systems

Dynamic Uncertainty Management in Digital Twin Engineering for Enhancing the Robustness and Resilience of Industrial Systems

Bouthayna EL Bouzaidi Tiali, Achraf Kallel, Stephen Creff, Nabil Anwer

IRT SystemX

LURPA, ENS Paris-Saclay, University Paris-Saclay

Poster #2: Digital Twins for Dimensional Metrology

Ladji Fofana, Katarina Josic, Nabil Anwer, Olivier Bruneau, Charyar Mehdi-Souzani, Romain Brault, Hichem Nouira

LURPA, ENS Paris-Saclay, University Paris-Saclay

Centre Technique des Industries Mécaniques (CETIM)

Laboratoire National de Métrologie et d’Essais (LNE)

Poster #3: Probabilistic estimation of health indicators of complex systems

Lucas THIL, Jesse READ and Rim KADDAH

Poster #4: Stochastic optimization of predictive maintenance under uncertainty

Wenbo WU, Sihem TEBBANI, Rim KADDAH and Miguel ANJOS

13h30

Digital Twins support for Model-Based Human-Systems Integration

Guy André Boy, Ph.D, INCOSE

I will present the digital twin (DT) concept to support model-based human systems integration (MB-HSI). A DT can be considered a model that enables the simulation and observation of various emerging socio-technical system (STS) activities. It can also be regarded as a vivid documentation system supporting design and operational processes. It is a software-based assistant system replacing traditional tools. From this perspective, a DT has become a mandatory tool for developing appropriate social-cognitive (multi-agent) models and methods that are helpful throughout the life cycle of contemporary sociotechnical systems. It enables accounting for the complexity and tangibility of human-centered context-sensitive architectures, combining procedural and declarative knowledge. Combining DT technology and HSI approaches requires a set of fundamental axioms, some theoretical abstractions, and valuable practical models, which are presented and illustrated in this paper. MB-HSI supported by DT technology is consequently defined as a process and a product at the confluence of several areas, such as systems engineering, human factors and ergonomics, information technology, and specific sectors, such as aerospace, health, and energy. More specifically, DT enables people and organizations to be considered early in the design and development processes and during the whole life cycle of an STS. I will provide a deeper foundation for DT technology based on an epistemological approach.

14h00

Digital-X (Models, shadows, twins), a set of critical resources to build generic frameworks for the prototyping, the evaluation, and the validation of CAV and AI-based systems.

Dominique Gruyer – Director of Research at the PICS-L laboratory – Univ Gustave Eiffel

In this presentation, in addition to the methodology and the generic framework for evaluation and validation, generation of datasets, generation of Digital-X, use cases and experiments already carried out involving the link between real and virtual will be presented. Issues of scenario generation, definition of requirements for simulation environments, and taxonomies for simulated environments will also be addressed.

14h30

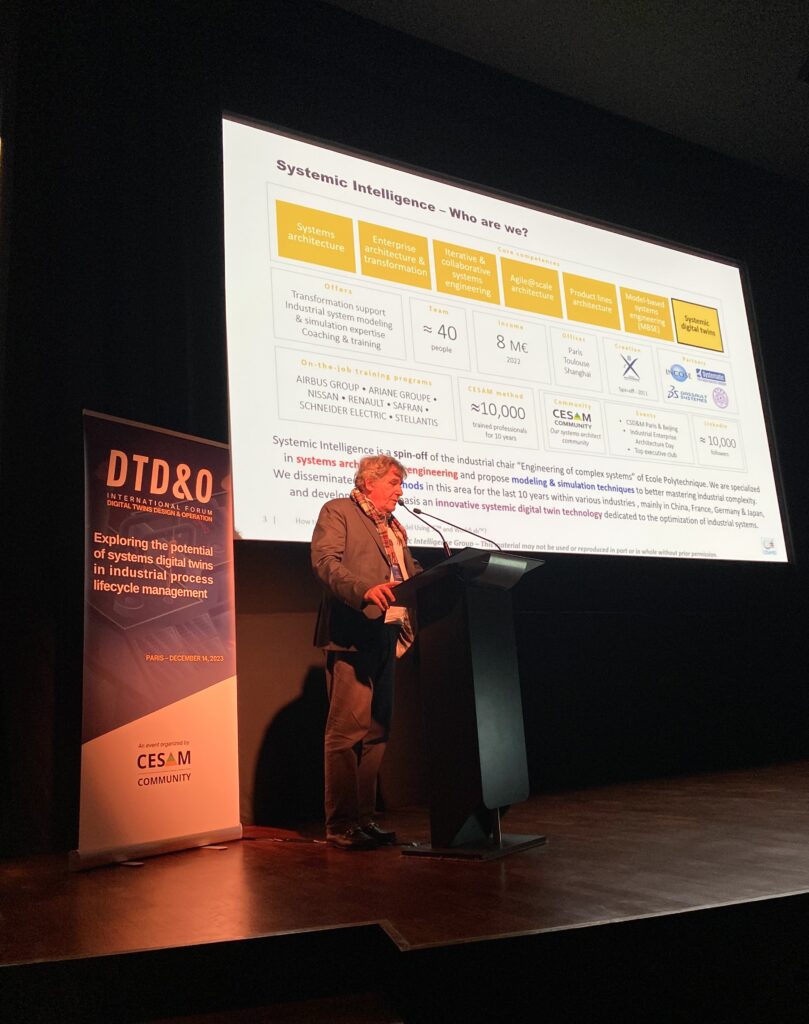

How to Optimize Industrial Operations? From Modelling to Simulation of Complex Industrial Systems

Daniel Krob, CEO, Systemic Intelligence group

The focus of this presentation will be: how does the transition from Model-Based Systems Engineering (MBSE) to the simulation and optimization of industrial operations occur through the innovative integration of systemic digital twins?

In an ever-evolving industrial landscape, optimizing complex and interdependent operational ecosystems has become a top priority for businesses. This includes managing supply chains, logistics, production systems, distribution, customer relations, and equipment maintenance, all while taking into account economic, political, social, technological, legal, and environmental factors.

The principles of MBSE are now widely applied in modeling complex industrial systems. However, the challenge lies in smoothly transitioning from this modeling to dynamic simulation—integrating stochastic dimensions—of business processes within an industrial system. This transition relies on the use of systemic digital twins, which leverage operational data and decision-making dashboards to enable in-depth analysis, precise evaluation, and continuous optimization of industrial system performance.

A practical example from an underwater mining operation will illustrate the effectiveness of this approach across various industrial sectors.

15h00

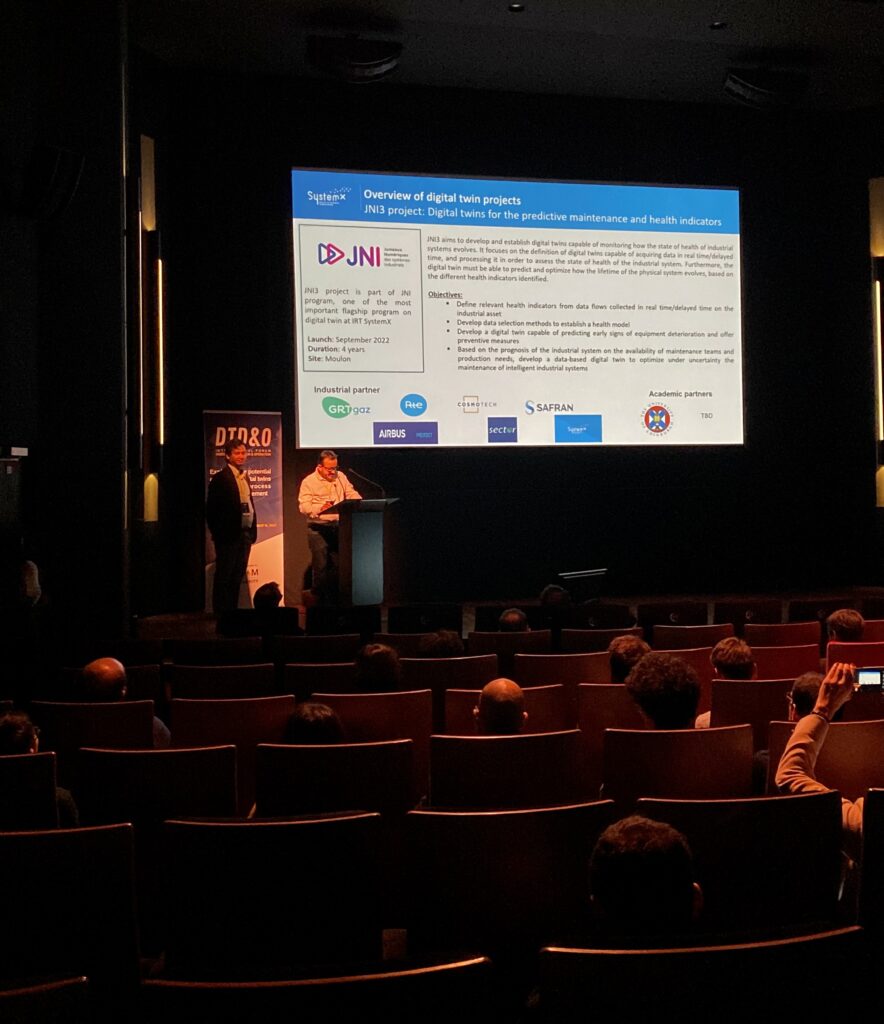

Digital Twin Program : GRT Gaz, French Transmission System Operator Case Studies.

Florent Brissaud, Expert, Sr Res. Eng. and R&D Manager, GRTgaz

Amira Ben Hamida, Senior R&I Program Coordinator, IRT SystemX

15h30

Coffee break

16h00

Multi-Scale Digital Twin: Experience with an Urban Living Lab

Mamadou Traore, Professor ; Master International Enterprise Engineering Manager, Université de Bordeaux

The ACT-DT project aims to develop and deploy an Urban Digital Twin, i.e., a set of data-rich digital models of the territory, capturing in real time the processes related to energy, mobility and activities qualified as urban. These models, used for monitoring, diagnosis, prediction, control and optimization purposes, are intended to provide support for public decision-making, but also to engage and serve citizens and private stakeholders, on issues related to sustainability and resilience, in the context of ever-growing climatic, geopolitical and health uncertainties. This presentation intends to provide some feedback on the development (still in progress) of this project.

16h30

Papers

The importance of 3D Visualization and XR in the industrial Digital Twin

Roberto Carlini – AVEVA (Schneider Electric Group) – ITALY

This presentation delves into the transformative impact of 3D Visualization and Extended Reality (XR) on the Industrial Digital Twin. It begins by outlining the fundamental challenges faced by industrial sectors in data visualization and analysis, highlighting how traditional methods fall short in addressing these issues. Through the integration of 3D Visualization and XR technologies, these challenges can be effectively mitigated, offering enhanced clarity and operational efficiency.

The concept of the Industrial Digital Twin is introduced as a digital representation of real-world physical products, systems, or processes. This digital replica unifies segmented data into a cohesive digital experience, facilitating improved collaboration and decision-making across the industrial lifecycle.

The presentation further explores the varied data visualization needs across different organizational roles, from site operations directors to data analysts, illustrating how tailored visualization solutions can meet these diverse requirements. The multiple layers of data visualization, blending IT, OT, and ET content, are discussed to demonstrate how comprehensive visualization can be achieved.

Detailed definitions and applications of 3D Visualization and XR are provided, emphasizing their roles in immersive design reviews, training, and operational connectivity. Real-world success stories from industry leaders such as Shell and BASF are showcased to illustrate the practical benefits and achievements of implementing these technologies.

Finally, the presentation looks towards the future, discussing the projected growth of the digital twin market and the increasing integration of 3D Visualization and XR technologies. The benefits for the industrial sector, including improved decision-making and enhanced training and safety, are highlighted as key drivers for this growth.

Smart Engineering Thinking in the Box Full Parametric Modelization

Hakim Bouhali – VEOLIA – United Arab Emirates

By leveraging real-time information, digitalization, and AI, we can significantly accelerate the tender process, improve cost estimations, and ensure that all project phases—from design to construction and commissioning—are both secure and efficient. Continuous feedback from site operations allows us to refine our designs in real time, ensuring continuous improvement and avoiding the need to “reinvent the wheel.” This approach helps streamline commissioning and operational management, providing valuable return on experience that directly enhances future designs. Additionally, our ability to visualize and present the future plant to clients ensures transparency, while reassuring top management that the design is under full control throughout the project lifecycle.

17h15

Digital Twin for assessing Energy transition scenarios at the scale of an Industry Value Chain

Thierry De Bernouis – BT WW Consulting – Expert Business Consultant, Dassault Systemes

How to reduce dependency on fossil energies while ensuring viable and sustainable economics for industry players?

Actors of economic sectors are facing systemic challenges toward their transition strategy.

We believe that Virtual Twin would help to educate, unite and guide the actions of stakeholders who for the moment act in isolation and often defend particular interests.

The uses of such Virtual Twin must help identify possible transformation trajectories, evaluate them and therefore enable informed decision-making, over sufficiently long-time horizons

The presentation will discuss:

. The usage of UAF to Model the different systems and sub-systems that interacts.

. The System of Systems approach to address the problem at different space and time-scales

. The System Dynamic approach to encompass the complexity, interconnectedness, and uncertainty

The presentation will be supported by an example of Virtual Twin for sustainable aviation transition path to de-carbonation

18h00

End

Book your seat right now!

Organizing & Program Committee

The conference venue

Business Center Paris Trocadero

112 Av. Kléber, 75116 Paris

Right next to the Trocadéro and the Eiffel Tower!

Public transport

– Lines 6 and 9: Trocadero

Public parking

– Parking Indigo Paris Place Victor Hugo

– Parking Indigo Paris Les Belles Feuilles